Your digital ecosystem for smart factories

Without agility and flexibility, companies have no chance in the digitalised economy. For manufacturing companies, too, the world is spinning faster and faster: shorter development cycles, increasingly complex production processes, massive competitive pressure. They are forced to keep increasing their efficiency and productivity.

With the Smart Factory Platform, msg Plaut is now providing industry with an IT marketplace that allows companies to purchase agile individual solutions that can be implemented quickly depending on their acute needs and thus keep their production processes up to date at all times.

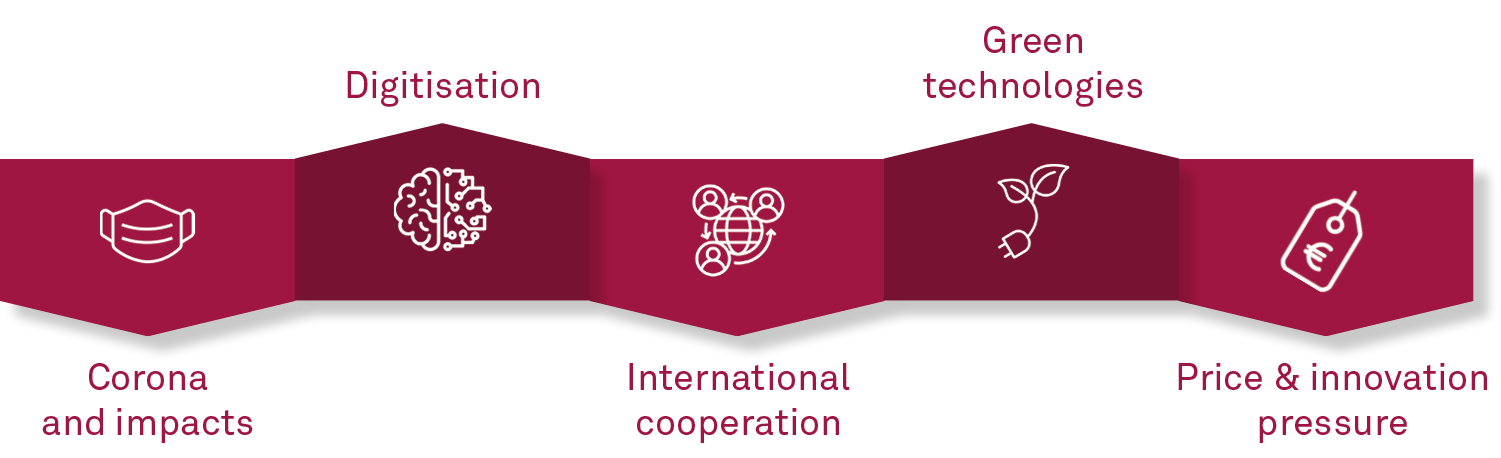

The 5 biggest challenges facing the industry

- Corona and impacts

- Digitisation

- International cooperation

- Green technologies

- Price & innovation pressure

2020 brought massive losses, but the current figures are optimistic.

Nevertheless, the situation remains volatile (Covid 19 mutations, climate change).

- Agility and flexibility are essential to remain marketable.

Cloud-based and digitised offerings:

- greater work efficiency

- stronger customer demand through modern offers

- increased revenue through freemium offers

- greater choice through new technologies

Cybercrime on the rise:

- Investments for security measures are well spent

New business models and fields as well as new ideas make a company fit for the future and for everything else the market has in store - nationally as well as internationally.

- Many potential cooperation partners are young, agile and broad-based

- Bundling and exchange of know-how strengthen own expertise

The requirements for companies in the area of environmental protection are becoming more and more stringent (also internationally).

- Only companies that do their part to protect the climate can survive in the long term.

- Competitive advantage through the use of new technologies for sustainable production and materials, CO2 offsetting or better working conditions

European companies are coming under enormous price pressure from Asia and the USA.

Here it is important to create one's own niches and balance this pressure with other assets.

- Brings positive differentiation from the competition

- USP with added value for a customer base that remains loyal despite the possibly higher price structure

Digital manufacturing is the answer

Global trends

- Global availability of products and services

- Local manufacturing & value creation

- High flexibility to follow changing policy frameworks

- Maximum and continuous cost optimisation

Quickly implementable, applicable use cases

- Data-centric production architecture

- Reduction of waste and continuous process optimisation with early warning systems

- Use of digital services from suppliers and partners for own process optimisation

- Increase OEE through better employee communication and transparency

Many companies deal with digital manufacturing, but do not manage to roll it out on their own. msg Plaut supports you in your transformation thanks to the Smart Factory platform.

One open platform for the rapid deployment of AI-based apps for production and logistics, directly usable and quality-assured from the Microsoft Azure Marketplace.

High transparency and flexibility in the manufacturing processes through Smart Analytics and early warning systems

Intelligent Apps for a Data Driven Enterprise

An ecosystem for "smart factories"

Apps as microservices

With the Smart Factory Platform (SFP), we provide industry with a marketplace for digital use cases in the form of Software as a Service (SaaS). As an IT marketplace, SFP enables companies to efficiently use applications in production and logistics.

Apps that are currently required can simply be purchased individually as a modular system and tried out. If an app is no longer needed, the subscription can simply be terminated. There is no long-term commitment to specific products or manufacturers, which usually allows less flexibility.

This way - thanks to agile individual solutions that can be implemented quickly - production processes always remain up to date.

All advantages at a glance

Minimum effort for digital lean manufacturing processes

Maximum flexibility through modular system

Transparency in production

Acceleration of the product launch

Reduction of the error rate

Increasing the overall system efficiency

The Smart Factory Platform Ecosystem

- Use SFP as a blueprint for your own digital manufacturing architecture

- Continuous expansion

- Extraction and use of data for own digital services

- Joint development of new use cases

- Validation of the use cases via the SFP marketplace

- Use of ideation and collaboration platforms

- Co-selling via the SFP

- More than 15 Digital Manufacturing Use Cases

- Use cases directly from the Azure Marketplace

- Minimal installations are required

- Security by design

- Automatic provisioning

- Smart Analytics and Prediction

- Virtual Production Reality

- Micro Services

- API management

Use Cases for the Smart Factory Platform

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overview & adjustment |

Overview & adjustment to competences and market changes |

For matching profiles, jobs, tasks & experts |

Gap / Potential Analysis |

|

Changed |

High transparency on human capital, permanent changes in skill requirements and structures |

High transparency and fast matching of competences to market needs & trends |

Quickly finding correct internal / external skillset, team, task or expert with suitable availability. |

Active gap analysis and staff development, consideration of learning interests, active offer of trainings |

|

Challenges in Human Capital Management |

Rigid skill data structure, distributed data sources with different data formats |

Lack of a unified competency model and constantly updating ontology |

Often manual, lack of data for optimal job/task/expert matching, lack of transparency to external sources |

Lack of merging of hard, soft skills & learning interests, lack of linkage with training provision. |

Benefit

- Analysis of the job roles of the employees necessary for the production processes

- Comparison with the existing skills model and market requirements

- Identifying ways to close the skills gap

Further Use Cases

Fast integration of legacy systems into modern data-based shop floor organisation. Modular kit of sensors, hardware, software and algorithms for the integration of AI applications.

Process mining of manufacturing processes to identify cost savings and enables process optimisation.